Laser Cutting Documentation Blog Entry

- nsyirah04

- Nov 6, 2022

- 3 min read

Updated: Nov 19, 2022

HIIII GUYS👋🏻!!! Its been so long since i've wrote a blog and i know you guys miss me hehe just kidding. Unfortunately, you have to read more of it🫢

In this Blog, I will describe: 1. The 4 important hazards associated to the operation of laser cutting machine and their respective safety control measures (administrative/engineering control). 2. The materials that can be cut and can’t be cut using laser cutting machine. 3. The steps including pictures on the operation of UNIVERSAL laser cutter, that consist of: a. Starting the compressor, turning on the laser cutter machine and fume extractor. b. Importing a .DXF file to coreldraw and modify the lines/fill for cutting and engraving. c. Sending the coreldraw drawing to laser cutter software and setting the laser cutter power, speed, PPI in the software. d. Starting the job on the laser cutter machine. e. DOs and DONTs when there’s flame/fire on the material being cut. 4. My Learning reflection on the laser cutter activities.

1. These are the 4 important hazards and the respective safety control measures on the operation of laser cutting machine:

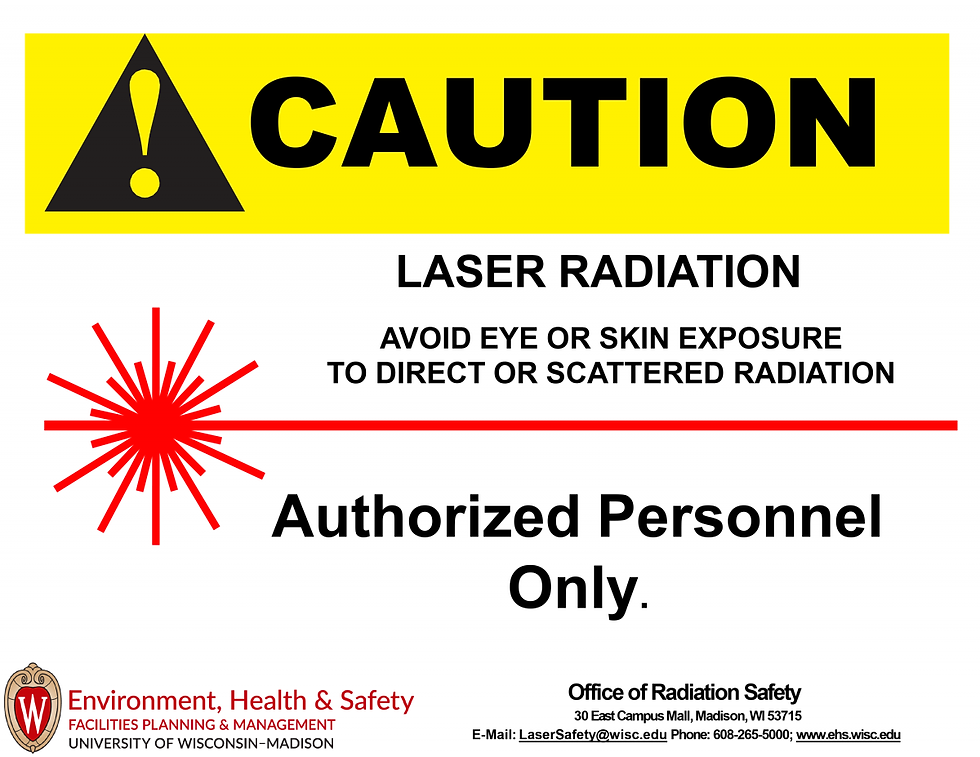

Hazards | Safety Control measures | Pictures to support the explanation |

| Administrative control: Do not stare at the beam while cutting, only glance at it once in a while |  |

2. Dirt and debris/material may cause fire | Administrative control: Ensure good housekeeping at all times, eg avoid build-up of rubbish that could burn. Administrative control: Educate Everyone on Fire Risks and Safety. |  |

3. Sharp edges could result in lacerations, and puncture wounds. | PPE: Wear working gloves while working |  |

4. Inhaling hazardous vapours & fumes | Engineering control: Laser cutter MUST be exhausted via FP&M approved duct work to the outside of the building. |  |

2. Below are the materials that can be cut/engraved using laser cutting machine in FabLab.

Material | Photo of material |

|  |

2. arcylic (up to 5mm) |  |

3. cardboard (burnt marks and fire may occur) |  |

4. Paper (burnt marks and fire may occur) -art card -technical board |  |

Below are the materials that can’t be cut/engraved using laser cutting machine in Fablab.

Material | photo of material |

|  |

2. materials that contains Chlorine (e.g. PVC) or Foam |  |

3. rubber |  |

3. Below are the steps on the operation of UNIVERSAL laser cutter machine in FabLab:

a. Starting the compressor, turning on the laser cutting machine and fume extractor.

Steps and description | Photos to support the description |

1)Start the compressor 2)Turn on the laser cutting machine 3)Turn on fume extractor |  |

b. Importing a .DXF file to coreldraw and modify the lines/fill for cutting and engraving

Steps and description | Photos to support the description |

1) Select File > Import > Select your .DXF file and press import |  |

2)Once imported, you will need to make decision on which one to vector cut, engrave or vector engrave |  Vector cut: R(255)G(0)B(0),Hairline Vector Engrave: R(0)G(255)B(0), Hairline Engrave: R(0)G(255)B(0), None   |

c. Sending the coreldraw drawing to laser cutter software and setting the laser cutter power, speed, PPI in the software.

Steps and description | Photos to support the description |

1)Click on File > Print |  |

2)Click on the Cogwheel>load>select material type and thickness |   |

3)click print | |

d. Starting the job on the laser cutter machine.

Steps and description | Photos to support the description |

1) Click on the small red button at top right to activate the machine |  |

2) Use focus tool to shift laser to the empty space where you want to cut and use move tool to shift your object |  |

3) Once ready, close the lid gently and press the start button |  |

e. DOs and DONTs when there’s flame/fire on the material being cut.

Dos | Image to support the description |

1) Immediately hit the emergency button/switch off the power |  |

2)Open up the cover to cut off the laser |  |

3) Attempt to blow off the flame ( only if you feel safe) |  |

4) Attempt to put out the fire by stepping on it aggresively |  |

5) Notify the staff immediately |  |

6)If the fire is severe and uncontrablle, use a fire extinguisher |  |

Donts | Images to support the description |

1) Do not pour water to kill fire as it might cause a short circuit |  |

2)Do not leave the fire unattended, it will just get bigger if you dont kill it |  |

3)Do not touch the fire with bare hands |  |

Below is my Learning Reflection on the laser cutter activities:

When i first heard of laser cutting, i was so excited to actually do it because it sound fun and interesting😋. I was looking forward to actually try it out however was also stress out when i heard that its a compentency test. "TEST" that word just gives me nothing but stress and i start to panic🥵. Before the competency test, we had to complete a Standard Operating Procedure (SOP) , this process helped me alot as i went through the universal guide to copy paste into my SOP. Watching the video in the practical package guide helped me understand and memorise the steps required to operate the universal laser cutting machine and also Coreldraw😎. After watching the video, i felt more confident for the competency test During the test, as i was waiting for my turn, i was so nervous and scared that i would messed it up😣 however i tried to stay calm. During my turn, i carefully did the steps required while referring to my SOP. I am so proud of myself that i managed to complete it efficiently without any problems and any help from Mr Louis💪🏻😁. My final product was a very small circle with "DCHE" vector engraved in the middle. I am deeply saddenned that i lost my first laser cutting product and did not managed to take picture of it to share it with you guys😔. Nevertheless, It was a fun experience and actually easier than i thought it was. I cant wait for my next laser cutting class and will look forward to it! 🤩🤩

Thank You for reading my blog! Hope you all liked it and stay tuned for my next one.🤓🤓

Comments