Blog 7

- nsyirah04

- Aug 22, 2022

- 3 min read

Updated: Oct 23, 2022

Hiiiii guys👋🏻!!! Im back with my last and final blog for this module yayyy. In this blog, i will be sharing with you guys my team's product from preliminary ideation to prototyping.💡📦⚒

Content that will be covered includes:

Operating principles and mechanism

Sketches, photo & videos of the fabrication process

Finish product

Why did we decide to create a Clarified butter maker?

During our brainstorming session on what products to be done, we realised that we need a healthier version of butter. Butter is one of the main ingredients for most foods and is frequently used, however, butter contains saturated and trans fats, both of which may increase the low-density lipoprotein (LDL) cholesterol, or bad cholesterol, in a person's blood. Hence when we researched, we found out that we can actually obtain

clarified butter which is a healthier and purer than normal butter and has a bold richness and a clean finish, with none of the muted milkiness of some traditional butters. Plus, it has a high smoke point, making it the better choice for high temp cooking. Clarified butter is rendered from butter to separate the milk solids and water from the butterfat. Typically, it is produced by melting butter and allowing the components to separate by density. It can be done manually however it's a very tedious process, hence our product will ease these process of seperation.

Design Specification

A specification is a set of documented requirements to be satisfied by a material, design, product, or service. It is a common preliminary part of any engineering design and product development process.

Good design specifications allow product designers to answer the following questions,

What are we building?

What should the final build achieve?

How do we measure success?

Types of specification to be included:

Physical dimensions

Functional/ performance specifications

Our Sketch

Our first & original sketch:

As you can see from the sketch shown above, this was our first orignal sketch without modifications. After SCAMPER, a creativity tool was introduced to us, we then made up 6 different ideas on how to improve on this product (can be seen below).

After doing feasibility analysis for all the 6 ideas above, we came down to 3 ideas which is the most feasible out of the 6.

These 3 ideas were:

Adding solenoid valve

Add filter/strainer

Substitute the inner cyclinder with an inverted cone-shape

We then decided to add these 3 ideas into our product and hence the sketch of the modified version can be seen below.

Modified version of our product:

Operating principles

The device above consists of a sensor, solenoid valve, filter/mesh, and a rounded shape compartment with red coil around it. The coil acts as a heating element to heat up the butter and allowing the components to separate by density. The mesh can separate the clarified butter or infuse clarified butter from the water and milk solids that will occur at the top of the procedure. By having a solenoid valve connected to a density/colour sensor which is connected to a switch it will be able to drain out the product which is the pure butter from the water and milk solids content without pouring or tilting it. The filter/mesh at the base separates the pure butter from the water and milk’s solid content so the outcome will just be pure butter without any residue. The red coil around the compartment acts as a heating element.

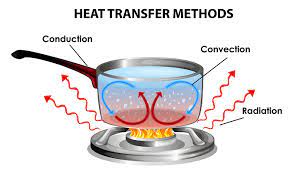

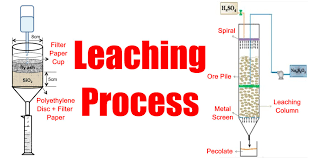

The chemical engineering principles involves in this product is

Heat transfer - The coil acts as a heating element to heat up the butter

Seperation density- It implies separation of lower-density particles from higher- density particles at a specific separating density

Leaching (only for herbs)

Filtration- Filter out the pure butter from its milk and water contents

Fabrication process of our prototype

For your information, we 3D printed our coil and inverted cone😎

Final product

TADAAA🤩🤩!! There we have it our final product that we planned and created everything from the start🥳. I was really happy to be able to see our ideas came to life and quite impress by my team as this product is not on the market hence we did everything purely by ourselves without any reference from the internet. I would like to thank my teammates for being there throughout this whole ICPD journey and always trying their best and making sure everything is working out well🥰. It has been a great journey in this module and we have finally came to the end of it. I would also like to thank my lecturer, Mr ting , for teaching me alot of things that i thought is very useful and is applicable to the real world.

Thank you for reading my last blog hope you guys enjoyed it🤓✌🏻

Comments